Worldclass botting and packaging solutions

Send us

Contact us

0086-13773222879

- Home

- Products

- Solution

- About

- Service

- News

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

DCGF18-18-6

The carbonated water filling machine adopts isobaric filling equipment that integrates cleaning, filling and capping. Based on the introduction, digestion and absorption of foreign advanced technology, according to the requirements of carbonated water filling process, it is an advanced filling equipment. It is mainly used for washing, filling and capping carbonated water such as soda, cola, sparkling wine and mineral water. With simple and reasonable structure, convenient and safe operation, stability and reliability, and convenient maintenance, it is the core equipment of large and medium-sized carbonated beverage plants.

The carbonated water filling machine adopts isobaric filling equipment that integrates cleaning, filling and capping. Based on the introduction, digestion and absorption of foreign advanced technology, according to the requirements of carbonated water filling process, it is an advanced filling equipment. It is mainly used for washing, filling and capping carbonated water such as soda, cola, sparkling wine and mineral water. With simple and reasonable structure, convenient and safe operation, stability and reliability, and convenient maintenance, it is the core equipment of large and medium-sized carbonated beverage plants.

Isobaric Carbonated Beverage Filling Machine

The isobaric filling machine generally maintains a certain filling pressure in the storage tank. When the container to be filled enters the filling machine, the container is first inflated, and the gas can be compressed air or carbon dioxide gas, with carbon dioxide gas being preferred. When the pressure in the container and the storage tank pressure is the same, that is, with the self-weight of the liquid through the opening of the filling valve filling. During the filling process, the gas inside the container will be exported smoothly and returned to the storage tank or the gas chamber.

Product Features

1.By 3-in-1 monoblock, the bottle goes through rinsing, filling and capping with little abrasion, and the transferring is stable, bottle change is easier.

2.The parts that direct contact with product are made of SUS 316L stainless steel and no technology corner pockets.

3.Rapid flow, highly filling precision, nicety liquid level without any liquid loss to satisfy the filling process demand.

4.Periodical gas exhaust and fast and slow snifting prevent product foaming.

5.Valve opening device is driven by the cylinder; open the valve in time according to the signal, movements are accurate and reliable.

6.Using deflection regulating valve, continuous control of fluid materials flow, so that hydraulic cylinder to maintain a smaller level fluctuations, ensure filling accuracy.

7.Simple internal filling valve chamber without springs ensure thorough cleaning & sanitation. Automatic CIP cups are highly efficient.

8.The capping head adopts constant.

Technical Parameter

| Model | DCGF18-18-6 |

| Capacity(500ml) | 5000-6000bottle per hour |

| Suitable bottle shapes | PET Circular or Square |

| Bottle diameter | 50~115mm |

| Bottle height | 120~320mm |

| Compressor air | 0.3~0.7Mpa |

| Washing medium | Pure Water |

| Filling type | Isobaric filling |

| Application | Carbonated drink / Sparkling water |

| Main motor power | 2.2kW |

| Overall dimensions | 2760*2060*2700 |

| Weight | 4500kg |

|Customer Production

| More Products

Focus on intergrated solution for beverage and liquid food, such as Mineral drinking water, Fruit Juice, Carbonated beverage,Energy drinks,Alcohol Wine, Beer, Edible oil, Dairy and Dauily care products, etc.

|Complete Line Solution

1.Pure water treatment filter system

This RO system is very important in the whole water project, we prefer you supply water analysis report from your local inspection department. This RO system we can make to match up with your water filling machine from capacity from 500L/Hr to 50000L/hr.

This system included sand filter, carbon filter, sodium exchanger, precision filter, Reverse Osmosis, UV, Ozone generator, Ozonized Tower, Pure water tank. This system is made of SUS304 or SUS316 material, thickness is 2.5mm-3mm we promised.We use GNP or CNP water pump, USA DOW or HYDRANAUTICS membrane, etc

2.Automatic blow molding machine for PET bottle:

Full automatic blowing machine from 2 cavity, 4 cavity, 6 cavity, 8 cavity, 9 cavity, etc from 2500BPH to 12000BPH for 500ml bottle.

3.Carbonated drink mixer and water chiller

Carbonation mixer: 1500L/Hr,2000L/Hr,3000L/Hr,5000L/Hr, etc. Co2 content is from 2.0-3.8

Water chiller: working with carbonation mixer, the cooling medium of water chiller going to heat plate exchanger of carbonation mixer to cooling carbonation drink to 3 degree to 8 degree (filling temperature).

4.Automatic OPP hot glue labeling machine:

5.High speed automatic PE film shrink packing machine:

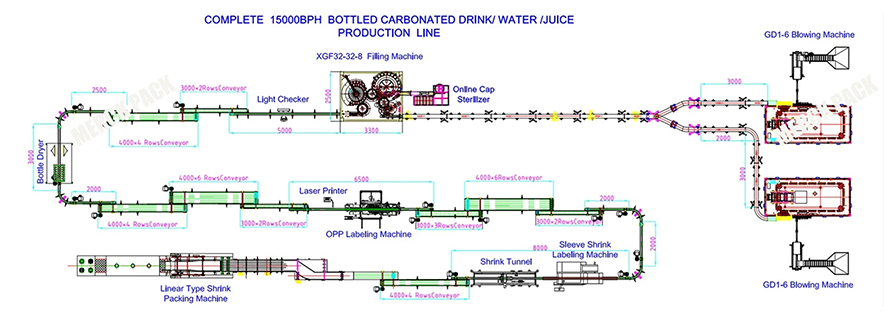

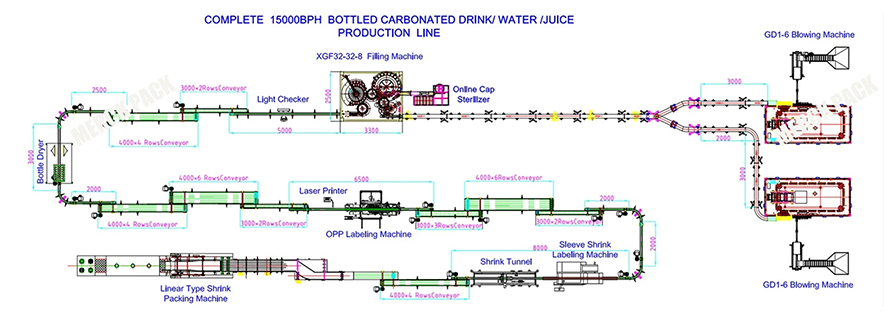

|Turkey Project

Carbonated Drink/Water/Juice Production Line

1.PET Bottle Blowing Machine ; 2.Washing Filling Capping Machine; 3.Cap elevator ; 4.Code sprayer ; 5.Conveyor System ;6.Automatic labeling Machine ; 7. Auotmatic PE film shrink wrapping machine ;

|Company Info

ZHANGJIAGANG MAERCK PACKING MACHINER CO.,LTD.

We are not only a machine manufacturer, we can also supply turnkey project according to customers’ request, including workshop design, machine layout design, water, gas, electric cable layout design, label and bottle design and so on. Our mission is to ensure customers’ plant properly working and help customers win their market.

Different capacity small bottle mineral water filling machine

| FAQ

1.Q For a new starter, how can you help me start and run a water or beverage bottling plant?

The carbonated water filling machine adopts isobaric filling equipment that integrates cleaning, filling and capping. Based on the introduction, digestion and absorption of foreign advanced technology, according to the requirements of carbonated water filling process, it is an advanced filling equipment. It is mainly used for washing, filling and capping carbonated water such as soda, cola, sparkling wine and mineral water. With simple and reasonable structure, convenient and safe operation, stability and reliability, and convenient maintenance, it is the core equipment of large and medium-sized carbonated beverage plants.

The carbonated water filling machine adopts isobaric filling equipment that integrates cleaning, filling and capping. Based on the introduction, digestion and absorption of foreign advanced technology, according to the requirements of carbonated water filling process, it is an advanced filling equipment. It is mainly used for washing, filling and capping carbonated water such as soda, cola, sparkling wine and mineral water. With simple and reasonable structure, convenient and safe operation, stability and reliability, and convenient maintenance, it is the core equipment of large and medium-sized carbonated beverage plants.

Isobaric Carbonated Beverage Filling Machine

The isobaric filling machine generally maintains a certain filling pressure in the storage tank. When the container to be filled enters the filling machine, the container is first inflated, and the gas can be compressed air or carbon dioxide gas, with carbon dioxide gas being preferred. When the pressure in the container and the storage tank pressure is the same, that is, with the self-weight of the liquid through the opening of the filling valve filling. During the filling process, the gas inside the container will be exported smoothly and returned to the storage tank or the gas chamber.

Product Features

1.By 3-in-1 monoblock, the bottle goes through rinsing, filling and capping with little abrasion, and the transferring is stable, bottle change is easier.

2.The parts that direct contact with product are made of SUS 316L stainless steel and no technology corner pockets.

3.Rapid flow, highly filling precision, nicety liquid level without any liquid loss to satisfy the filling process demand.

4.Periodical gas exhaust and fast and slow snifting prevent product foaming.

5.Valve opening device is driven by the cylinder; open the valve in time according to the signal, movements are accurate and reliable.

6.Using deflection regulating valve, continuous control of fluid materials flow, so that hydraulic cylinder to maintain a smaller level fluctuations, ensure filling accuracy.

7.Simple internal filling valve chamber without springs ensure thorough cleaning & sanitation. Automatic CIP cups are highly efficient.

8.The capping head adopts constant.

Technical Parameter

| Model | DCGF18-18-6 |

| Capacity(500ml) | 5000-6000bottle per hour |

| Suitable bottle shapes | PET Circular or Square |

| Bottle diameter | 50~115mm |

| Bottle height | 120~320mm |

| Compressor air | 0.3~0.7Mpa |

| Washing medium | Pure Water |

| Filling type | Isobaric filling |

| Application | Carbonated drink / Sparkling water |

| Main motor power | 2.2kW |

| Overall dimensions | 2760*2060*2700 |

| Weight | 4500kg |

|Customer Production

| More Products

Focus on intergrated solution for beverage and liquid food, such as Mineral drinking water, Fruit Juice, Carbonated beverage,Energy drinks,Alcohol Wine, Beer, Edible oil, Dairy and Dauily care products, etc.

|Complete Line Solution

1.Pure water treatment filter system

This RO system is very important in the whole water project, we prefer you supply water analysis report from your local inspection department. This RO system we can make to match up with your water filling machine from capacity from 500L/Hr to 50000L/hr.

This system included sand filter, carbon filter, sodium exchanger, precision filter, Reverse Osmosis, UV, Ozone generator, Ozonized Tower, Pure water tank. This system is made of SUS304 or SUS316 material, thickness is 2.5mm-3mm we promised.We use GNP or CNP water pump, USA DOW or HYDRANAUTICS membrane, etc

2.Automatic blow molding machine for PET bottle:

Full automatic blowing machine from 2 cavity, 4 cavity, 6 cavity, 8 cavity, 9 cavity, etc from 2500BPH to 12000BPH for 500ml bottle.

3.Carbonated drink mixer and water chiller

Carbonation mixer: 1500L/Hr,2000L/Hr,3000L/Hr,5000L/Hr, etc. Co2 content is from 2.0-3.8

Water chiller: working with carbonation mixer, the cooling medium of water chiller going to heat plate exchanger of carbonation mixer to cooling carbonation drink to 3 degree to 8 degree (filling temperature).

4.Automatic OPP hot glue labeling machine:

5.High speed automatic PE film shrink packing machine:

|Turkey Project

Carbonated Drink/Water/Juice Production Line

1.PET Bottle Blowing Machine ; 2.Washing Filling Capping Machine; 3.Cap elevator ; 4.Code sprayer ; 5.Conveyor System ;6.Automatic labeling Machine ; 7. Auotmatic PE film shrink wrapping machine ;

|Company Info

ZHANGJIAGANG MAERCK PACKING MACHINER CO.,LTD.

We are not only a machine manufacturer, we can also supply turnkey project according to customers’ request, including workshop design, machine layout design, water, gas, electric cable layout design, label and bottle design and so on. Our mission is to ensure customers’ plant properly working and help customers win their market.

Different capacity small bottle mineral water filling machine

| FAQ

1.Q For a new starter, how can you help me start and run a water or beverage bottling plant?

content is empty!