* Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

* Reverse Osmosis (First , Second stage) + Ultrafiltration System + Water Ionizer (Electrolyzed water machine)

* UV sterilizer + Ozone sterilizer + Ozone mixing tower +

* Finished water tank + Pure water pump +Titanium rod filter

According to customer's water source analysis report and the final water standard required ,we will recommend customer the suitable water treatment plants.

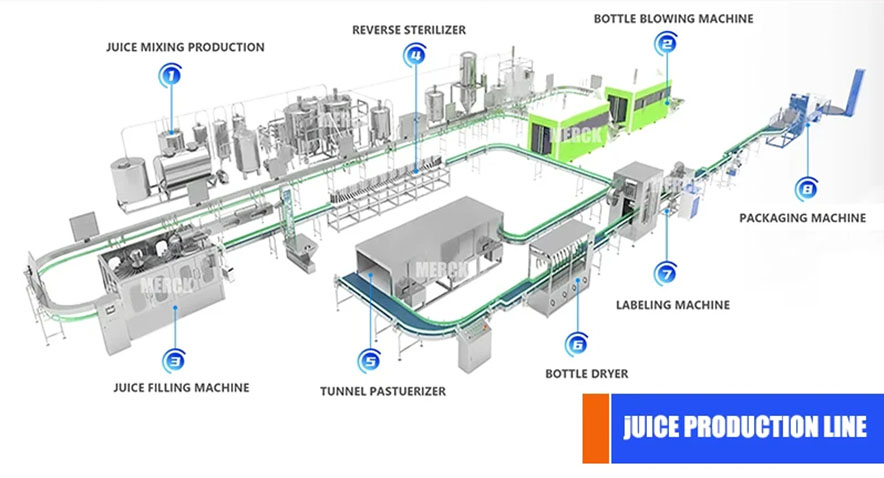

Automatic Stretch Bottle Blow Molding Machine (liner , rotary , servo type)

NB series of fully automatic, semi-automatic PET blow molding machines and other 10L-20L Full Automatic Blow Molding Machine with output from 1000 to 24000 bottles per hour, which can satisfy different customers' requirements. our products Certificated by CE. In order to meet customers’ specific requirements, factory offer product capacity ranges from 50ml to 30L, suitable for all kinds of PET bottles which contain mineral water, carbonated beverages, fruit juice, teas, edible oils cosmetics, detergents, and wide-mouth jar, etc. It is an ideal choice for large beverage factories, mineral water companies, and PET packaging enterprises.

2 / Top quality: Electrical stretching for bottle integrity, full material distribution control and performance

3 / Fast output: Boosted uptime and speed (up to 2,400 bottles/mould/hour)

4 / Efficient consumption: Up to 45 % less electricity and 35 % less compressed air

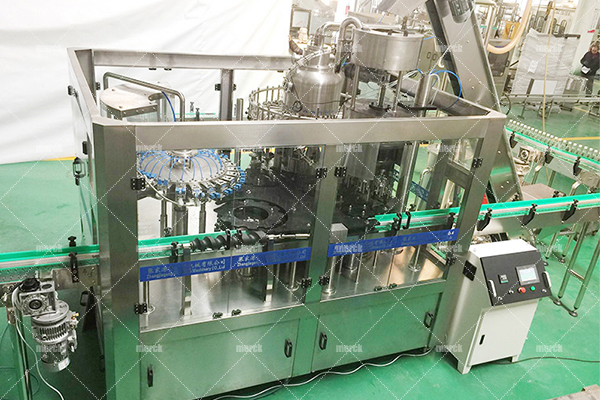

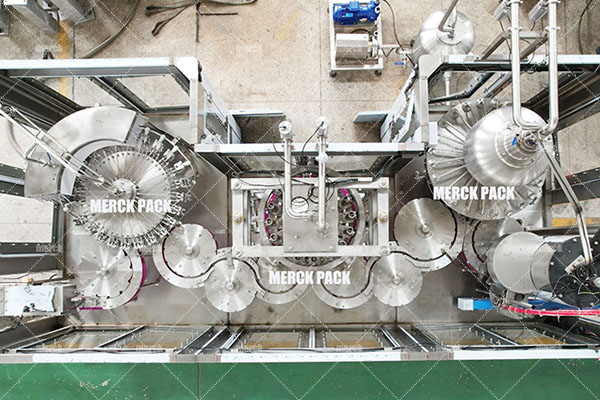

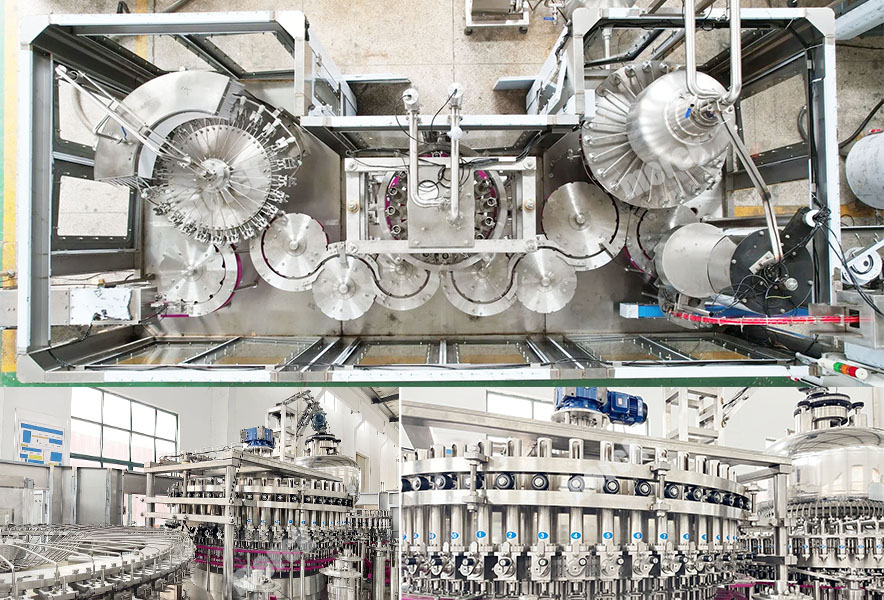

RGFR Bottle Juice Filling Machine [ Washing Filling Capping 3 in 1 Monoblock Machine ]

The equipment is used in production of non-soda drink , fruit juice, fruit wine, minerals and the most advanced technology from Japan and Germany is employed in the design. The gravity fixed liquid surface filling is used. The filling is fast, the amount of liquid is accurately controlled and the dropping and leakage are avoided.

Spring cramps are used in the bottle washing process. The empty bottles can be turned over180~ along the conveying rail. There are two times of internal and external washing, the efficiency of bottle washing is high.

The magnetic torque is used for screw capping. The power of screw capping can be adjusted without steps. The power of the screw capping can also be fixed, and the caps will not be damaged, the capping is reliable.

The whole machine is controlled by PLC with touch-screen as the human-machine interface. The amount of the drinks in the storage tank can be controlled automatically. The filling and capping will be stopped automatically when there is no bottle. When bottles are cramped wrongly or when caps are not available, the machine can be stopped automatically.

The frequency changing technology is used to adjust the operation speed steplessly. The production capacity can be displayed digitally and can be adjusted conveniently.

Features

2 / Optimum uptime: 30 % reduction in changeover and maintenance downtime

3 / Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

4 / Hygiene improvement through volume control and contactless filling

5 / Automatic dummy bottles: Safer, easier cleaning procedures

6 / Automatic bottle changeover improves uptime

Automatic Bottle Labeling Machine

Automatic Bottle Labeling Machine

As customer request and market demand , we offer PVC /PET sleeve srhink labeling machine , BOPP hot glue labeling machine ,Adhesive stick labeling machine ,Wet glue labeling machine .All machines are equipped with SIEMENS / Schneider / Panasonic PLC & Human touch screen , ABB , SEW , SANYO servo motor , up to three labelling stations and 24 configurations, can generate outputs of up to 36,000 containers per hour, when standalone, at an efficiency rate of 98%.

Benefits

1 / Greater performance and ergonomics

2 / Boasted production uptime

3 / Sustainable and quality production

Automatic Bottle Packing Machine

Automatic Bottle Packing Machine

Once your beverage product has been filled and the bottle has been labelled, the primary package is gently transferred using conveyors to its secondary packaging process. The final result is the package the customer sees at the point of sale, so it needs to grab their attention. These packs ensure protection from elements such as weather, pressure and temperature changes.Whether you choose shrink-printed film, nested packs or wraparound cartons, NAVAN Machine packers gently feed bottles to ensure durable and cost-effective packs.

BENEFITS.

1 / Transparent plastic film shrink wrapper packing machine

2 / Printed plastic film shrink wrapper packing machine

3 / Half tray shrink wrapper packing machine

4 / One piece carton packing machine with melting glue sealing

5 / One piece carton packing machine with plastic tape sealing

6 / Online palletizer and stretch wrapping packing machines