Worldclass botting and packaging solutions

Send us

Contact us

0086-13773222879

- Home

- Products

- Solution

- About

- Service

- News

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

CGF40-40-10

MERCK

| Product Description

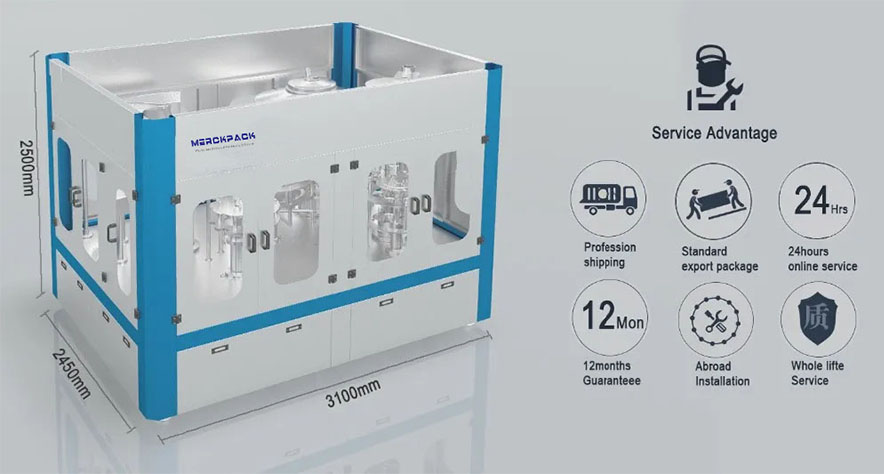

A to Z Automatic Complete Bottled Pure Drinking Mineral Water Filling Production Line Bottle Water Filling Machine

Full automatic water filling machine for PET bottle integrates the functions of rinsing, filling and capping together. Based on advanced technology overseas and designed according to the filling processing demands of mineral water, pure water, drinking water etc.

Water Filling Machine,Natural Bottle Water Filling Capping Labeling Machine Line Plant Cost,Small Business Bottled Washing Filling And Capping Labeling Packing Machinery Price Plant Equipment Production Line

| Product Details

|Technical Parameter

| Mineral Water/washing/rinsing Bottling Filling Capping Label/labeling Packing/package Machine | |

| Model | CGF40-40-10 |

| Capacity: (for 500ml) | 18000-20000bottles/hour |

| Suitable bottle shapes: | PET Circular or Square |

| Bottle volume: | 500-2000ml |

| Bottle Diameter: | 50~115mm |

| Bottle Height: | 120~320mm |

| Compressor air: | 0.3~0.7Mpa |

| Washing medium: | Pure Water |

| Rinsing pressure: | 0.06~0.2Mpa |

| Application: | Pure/Mineral drink water |

| Main motor power: | 7.5kw |

| Overall Dimensions: | 4360*3300*2700mm |

Different capacity small bottle mineral water filling machine

|Complete Line Solution

1.WATER TREATMENT PLANT

According to customer's water source analysis report and the final water standard required ,we will suggest customer to choose the suitable water treatment system plants.

2.PET BOTTLE BLOWING MACHINE

Bottle blowing machine is to make plastic bottles for mineral water, carbonated drink, juice and so on. It is widely used in the food and beverage package industry.

3.SMALL BOTTLE MINERAL WATER FILLING CAPPING MACHINE

This machine is specially designed for the filling of pure water, mineral water and other non-gas and sugar free bveverages in bottles, it is an integrated equipment for bottle washing, filling and capping.Automatic making Pet Plastic Drinking Mineral Water bottling machine Production Line/Bottle Water Filling Machine.Bottle Liquid Filling Machine Price For Drinking Pure Mineral Water/beverage Bottling Plant.500ML Full Automatic 3 in1 Mini Small Business Scale Bottle Mineral Spring Pure Table Drinking Water Filling Machine Price.

4.HOT GLUE MELTING LABELING MACHINE

1. Adopt the overall vertical labeling mode,automatically label cutting, automatic labeling.

2. Microcomputer continuously variable control system, automatic detection in accordance with the feed, automatic adjustment of the production rate to maintain the labeling machine always in the best production rate.

3. Applying the star-wheel feeding, to ensure not pour the bottle under high speed.

4. Host Controller working with the frequency three-phase motor to control transmission.

5. Label supply applying the servo motor synchronous tracking cutting, specially designed vacuum drum high-speed absorption, accurate and stable labeling.

5.LASER DATE PRINTER

The CO2 laser printer marking machines are powerful and versatile, they deliver flexible, high speed, high quality coding across a wide variety of materials with the ability to produce multiple lines of text. Our laser marking machines are designed to fit in limited spaces and integrate into a variety of production lines.

6.BOTTLE PACKING MACHINE

Bottle packing machine is the last step for production line usually. There are different ways for packing such as shrink packing, carton packing, half- tray wuth shrink packing etc. Bottle packaging machine speed usually from 10PPM up to 80PPM, all confirgurations we used are world famous brand, to ensure the machine quality.

7.Palletizing Machine

This machine is mainly used in various high speed production line palletizing and storage.It uses side-entry box mode, which covers small area, has more advanced structure, more portable and stable movement, and low energy consumption.The method of palletizing is simple and convenient to adjust.It can be realized in man-machine inter face hill.At the same time, the systems suitable for both carton and film-wrapped products.

More Products

Like Carbonated beverage , soda water ,energy drinks ...

Capacity :1000bph~20000bph

Like Fruit juice ,NFC juice , juice with pulp ...

Capacity:500bph~30000bph

Like PET bottle beer ,Glass bottle beer ,Can beer ...

Capacity:500bph~20000bph

|Turnkey Solutions

|Customer Production Site

| Bottled Water Filling machine Packing&Shipping

| Company Profile

ZHANGJIAGANG MAERCK PACKING MACHINER CO.,LTD.

We are not only a machine manufacturer, we can also supply turnkey project according to customers’ request, including workshop design, machine layout design, water, gas, electric cable layout design, label and bottle design and so on. Our mission is to ensure customers’ plant properly working and help customers win their market.

| About Service

| FAQ

1.Q For a new starter, how can you help me start and run a water or beverage bottling plant?

| Product Description

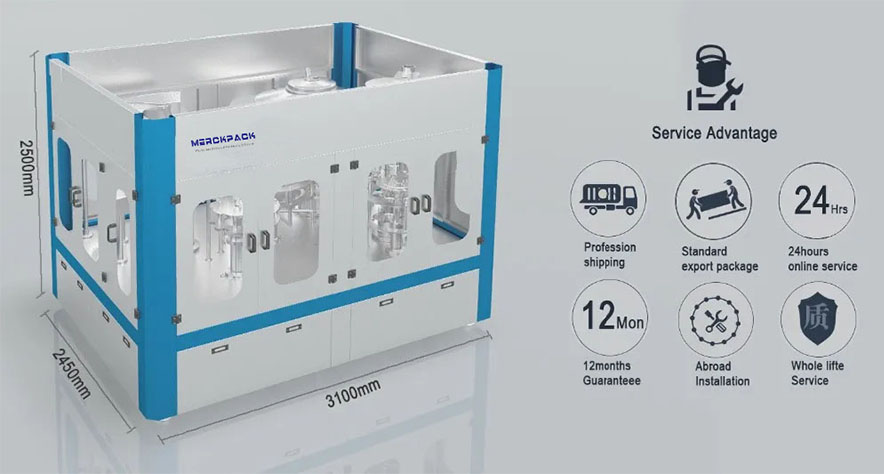

A to Z Automatic Complete Bottled Pure Drinking Mineral Water Filling Production Line Bottle Water Filling Machine

Full automatic water filling machine for PET bottle integrates the functions of rinsing, filling and capping together. Based on advanced technology overseas and designed according to the filling processing demands of mineral water, pure water, drinking water etc.

Water Filling Machine,Natural Bottle Water Filling Capping Labeling Machine Line Plant Cost,Small Business Bottled Washing Filling And Capping Labeling Packing Machinery Price Plant Equipment Production Line

| Product Details

|Technical Parameter

| Mineral Water/washing/rinsing Bottling Filling Capping Label/labeling Packing/package Machine | |

| Model | CGF40-40-10 |

| Capacity: (for 500ml) | 18000-20000bottles/hour |

| Suitable bottle shapes: | PET Circular or Square |

| Bottle volume: | 500-2000ml |

| Bottle Diameter: | 50~115mm |

| Bottle Height: | 120~320mm |

| Compressor air: | 0.3~0.7Mpa |

| Washing medium: | Pure Water |

| Rinsing pressure: | 0.06~0.2Mpa |

| Application: | Pure/Mineral drink water |

| Main motor power: | 7.5kw |

| Overall Dimensions: | 4360*3300*2700mm |

Different capacity small bottle mineral water filling machine

|Complete Line Solution

1.WATER TREATMENT PLANT

According to customer's water source analysis report and the final water standard required ,we will suggest customer to choose the suitable water treatment system plants.

2.PET BOTTLE BLOWING MACHINE

Bottle blowing machine is to make plastic bottles for mineral water, carbonated drink, juice and so on. It is widely used in the food and beverage package industry.

3.SMALL BOTTLE MINERAL WATER FILLING CAPPING MACHINE

This machine is specially designed for the filling of pure water, mineral water and other non-gas and sugar free bveverages in bottles, it is an integrated equipment for bottle washing, filling and capping.Automatic making Pet Plastic Drinking Mineral Water bottling machine Production Line/Bottle Water Filling Machine.Bottle Liquid Filling Machine Price For Drinking Pure Mineral Water/beverage Bottling Plant.500ML Full Automatic 3 in1 Mini Small Business Scale Bottle Mineral Spring Pure Table Drinking Water Filling Machine Price.

4.HOT GLUE MELTING LABELING MACHINE

1. Adopt the overall vertical labeling mode,automatically label cutting, automatic labeling.

2. Microcomputer continuously variable control system, automatic detection in accordance with the feed, automatic adjustment of the production rate to maintain the labeling machine always in the best production rate.

3. Applying the star-wheel feeding, to ensure not pour the bottle under high speed.

4. Host Controller working with the frequency three-phase motor to control transmission.

5. Label supply applying the servo motor synchronous tracking cutting, specially designed vacuum drum high-speed absorption, accurate and stable labeling.

5.LASER DATE PRINTER

The CO2 laser printer marking machines are powerful and versatile, they deliver flexible, high speed, high quality coding across a wide variety of materials with the ability to produce multiple lines of text. Our laser marking machines are designed to fit in limited spaces and integrate into a variety of production lines.

6.BOTTLE PACKING MACHINE

Bottle packing machine is the last step for production line usually. There are different ways for packing such as shrink packing, carton packing, half- tray wuth shrink packing etc. Bottle packaging machine speed usually from 10PPM up to 80PPM, all confirgurations we used are world famous brand, to ensure the machine quality.

7.Palletizing Machine

This machine is mainly used in various high speed production line palletizing and storage.It uses side-entry box mode, which covers small area, has more advanced structure, more portable and stable movement, and low energy consumption.The method of palletizing is simple and convenient to adjust.It can be realized in man-machine inter face hill.At the same time, the systems suitable for both carton and film-wrapped products.

More Products

Like Carbonated beverage , soda water ,energy drinks ...

Capacity :1000bph~20000bph

Like Fruit juice ,NFC juice , juice with pulp ...

Capacity:500bph~30000bph

Like PET bottle beer ,Glass bottle beer ,Can beer ...

Capacity:500bph~20000bph

|Turnkey Solutions

|Customer Production Site

| Bottled Water Filling machine Packing&Shipping

| Company Profile

ZHANGJIAGANG MAERCK PACKING MACHINER CO.,LTD.

We are not only a machine manufacturer, we can also supply turnkey project according to customers’ request, including workshop design, machine layout design, water, gas, electric cable layout design, label and bottle design and so on. Our mission is to ensure customers’ plant properly working and help customers win their market.

| About Service

| FAQ

1.Q For a new starter, how can you help me start and run a water or beverage bottling plant?

content is empty!