Worldclass botting and packaging solutions

Send us

Contact us

0086-13773222879

- Home

- Products

- Solution

- About

- Service

- News

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

HLG

MERCK

| Product Description

This ultra-high temperature sterlizer is PLC controller, with optional capacity from 0.5t/h to 20t/h. The whole system is automatically controlled in four units, pre-sterilization, normal production, water recycling and CIP. With technical requirement for acidic products and temperature control for water, sealed pre-sterilization system for ultra-high temperature water is equipped to ensure high efficiency. CIP and SIP are designed for the demand of cleaning and sterilization.

Main componets are from world famous suppliers as Alfa Laval, APV, SPIRAX, SIEMENS, FESTO etc.

| Product Details

|Technical Parameter

| Model | UHT-10B | UHT-26B | UHT-38B | UHT-45B | UHT-105B |

|---|---|---|---|---|---|

| Output capacity | 1t/h | 2t/h | 3t/h | 5t/h | 10t/h |

| Heat exchangingarea | 13㎡ | 26㎡ | 38㎡ | 55㎡ | 105㎡ |

| Temperature of material inlet | 5°C | 5°C | 5°C | 5°C | 5°C |

| Temperature of material outlet | 5°C | 5°C | 5°C | 5°C | 5°C |

| Sterilizer temperature | 137°C | 137°C | 137°C | 137°C | 137°C |

| Heat preservation period | 4s | 4s | 4s | 4s | 4s |

| Ice water temperature | 1°C | 1°C | 1°C | 1°C | 1°C |

| Ice water consumption | 3t | 3t | 3t | 3t | 3t |

| Hot water consumption | 2t | 2t | 2t | 1t | 1t |

| Connection size | 32mm | 38mm | 51mm | 51mm | 63mm |

| Steam pressure | >0.6 | >0.6 | >0.6 | >0.6 | >0.6 |

| Outlien dimensions | 1.5x1.5x1.8m | 2.2x2x1.8m | 2.6x2x2.2m | 2.8x2x2.3m | 3.2x2x2.2m |

This ultra-high temperature sterlizer can be connect with separator, homogenizer, flash evaporator asser ect.this unit is used as pasteurizer (widely used in fresh milk, milk beverage, juice, tea, alcohol, ice cream ect.) and also pre-sterilize material when producing Pasteurized milk (long life milk).

This machine has features of high heat recovery, lower energy cost, strict design on the construction and easy operation, simple maintenance.

More Products

bottle blowing machine

water tratement system

bottle filling machine

carbonated drink filling machine

5gallon big barrel filling machine

cans filling sealing machine

opp labeling machine

Linear shrink warpping with tray

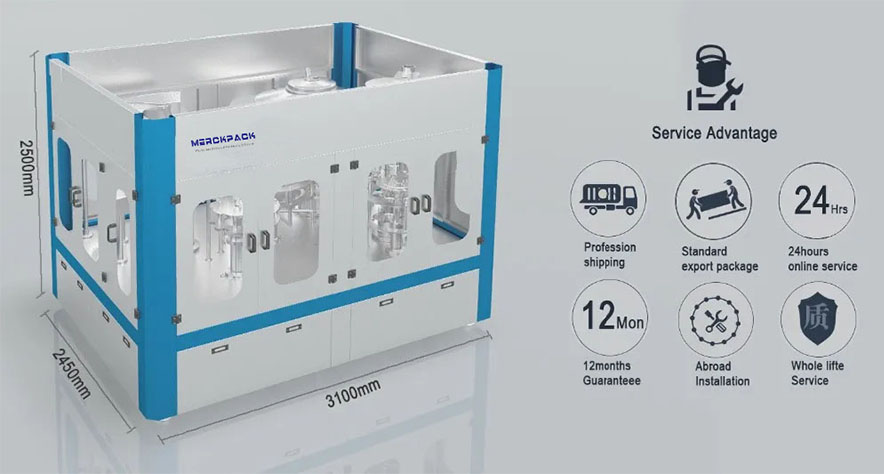

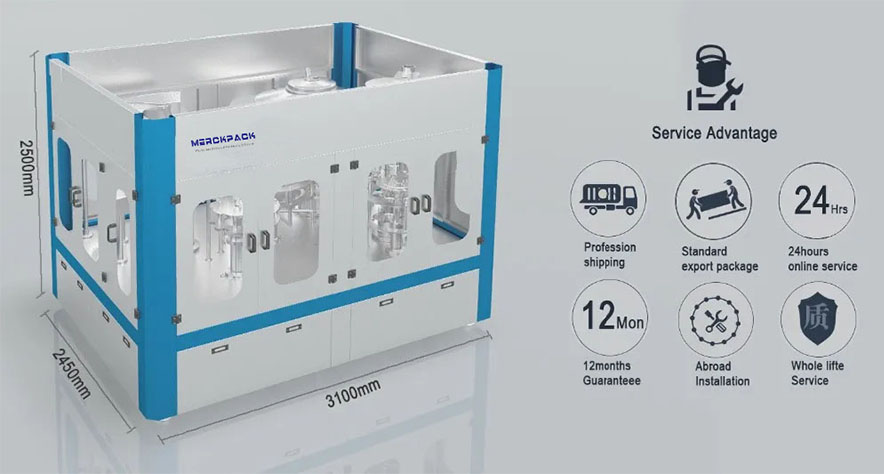

| Auto Bottle Firm Shrink Wrapping Machine Packing&Shipping

| Company Profile

ZHANGJIAGANG MAERCK MACHINER CO.,LTD.

We are not only a machine manufacturer, we can also supply turnkey project according to customers’ request, including workshop design, machine layout design, water, gas, electric cable layout design, label and bottle design and so on. Our mission is to ensure customers’ plant properly working and help customers win their market.

Different capacity small bottle mineral water filling machine

| About Service

| FAQ

1.Q For a new starter, how can you help me start and run a water or beverage bottling plant?

| Product Description

This ultra-high temperature sterlizer is PLC controller, with optional capacity from 0.5t/h to 20t/h. The whole system is automatically controlled in four units, pre-sterilization, normal production, water recycling and CIP. With technical requirement for acidic products and temperature control for water, sealed pre-sterilization system for ultra-high temperature water is equipped to ensure high efficiency. CIP and SIP are designed for the demand of cleaning and sterilization.

Main componets are from world famous suppliers as Alfa Laval, APV, SPIRAX, SIEMENS, FESTO etc.

| Product Details

|Technical Parameter

| Model | UHT-10B | UHT-26B | UHT-38B | UHT-45B | UHT-105B |

|---|---|---|---|---|---|

| Output capacity | 1t/h | 2t/h | 3t/h | 5t/h | 10t/h |

| Heat exchangingarea | 13㎡ | 26㎡ | 38㎡ | 55㎡ | 105㎡ |

| Temperature of material inlet | 5°C | 5°C | 5°C | 5°C | 5°C |

| Temperature of material outlet | 5°C | 5°C | 5°C | 5°C | 5°C |

| Sterilizer temperature | 137°C | 137°C | 137°C | 137°C | 137°C |

| Heat preservation period | 4s | 4s | 4s | 4s | 4s |

| Ice water temperature | 1°C | 1°C | 1°C | 1°C | 1°C |

| Ice water consumption | 3t | 3t | 3t | 3t | 3t |

| Hot water consumption | 2t | 2t | 2t | 1t | 1t |

| Connection size | 32mm | 38mm | 51mm | 51mm | 63mm |

| Steam pressure | >0.6 | >0.6 | >0.6 | >0.6 | >0.6 |

| Outlien dimensions | 1.5x1.5x1.8m | 2.2x2x1.8m | 2.6x2x2.2m | 2.8x2x2.3m | 3.2x2x2.2m |

This ultra-high temperature sterlizer can be connect with separator, homogenizer, flash evaporator asser ect.this unit is used as pasteurizer (widely used in fresh milk, milk beverage, juice, tea, alcohol, ice cream ect.) and also pre-sterilize material when producing Pasteurized milk (long life milk).

This machine has features of high heat recovery, lower energy cost, strict design on the construction and easy operation, simple maintenance.

More Products

bottle blowing machine

water tratement system

bottle filling machine

carbonated drink filling machine

5gallon big barrel filling machine

cans filling sealing machine

opp labeling machine

Linear shrink warpping with tray

| Auto Bottle Firm Shrink Wrapping Machine Packing&Shipping

| Company Profile

ZHANGJIAGANG MAERCK MACHINER CO.,LTD.

We are not only a machine manufacturer, we can also supply turnkey project according to customers’ request, including workshop design, machine layout design, water, gas, electric cable layout design, label and bottle design and so on. Our mission is to ensure customers’ plant properly working and help customers win their market.

Different capacity small bottle mineral water filling machine

| About Service

| FAQ

1.Q For a new starter, how can you help me start and run a water or beverage bottling plant?

content is empty!