Full automatic aluminum can carbonated drink filling machine / CO2 soda beverage canning sealing equipment

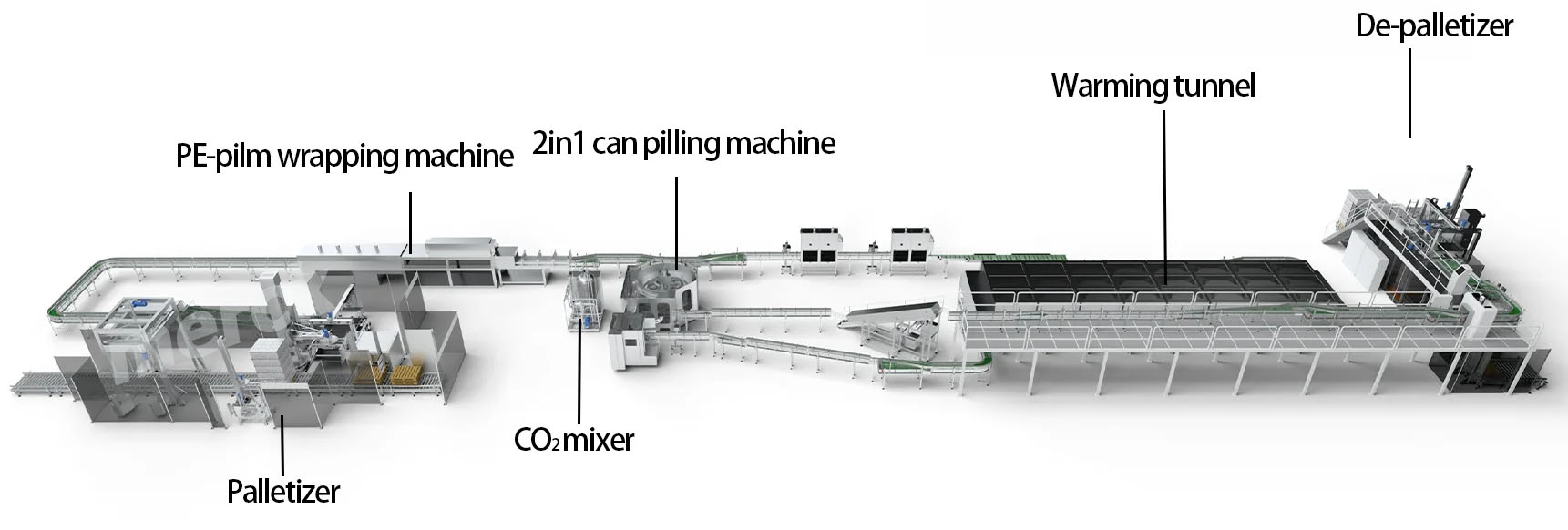

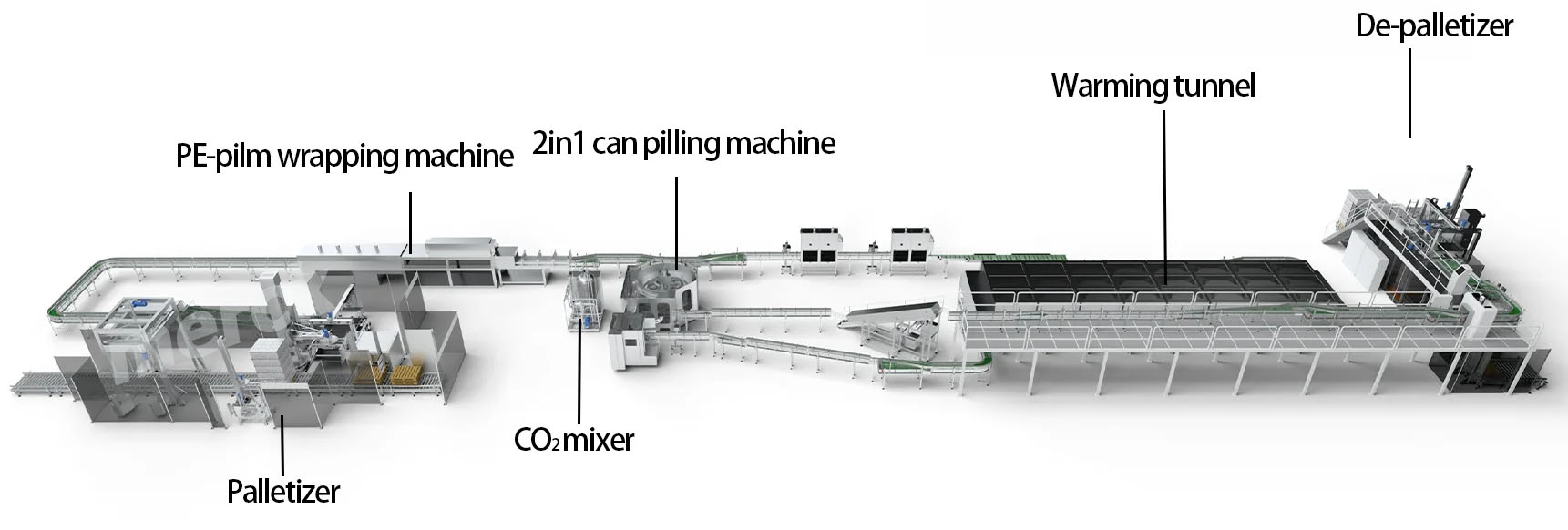

We supply complete solution for pop cans / tin can filling and package, including can depalletizer, can rinsing machine, can filling & sealing monoblock machine, leakage check, liquid nitrogen dosing machine, can warmer, film wrapping system.

Product Features

The 2 in 1 can filler and sealer is developed on the basis of digesting and absorbing advanced technology introducing from abroad and is with international advanced level. It is mainly used for filling carbonated containing drink in tin cans, such as water, juice, soda water ,soft drink,sparkling water and so on. The filling way is normal pressure. It adopts the automatic PLC touch screen control system, and the speed can be regulated forever as customer requirements within the scope. It is set with 24 filling heads and 6 sealing heads. The filling valves are adopted special for filling juice and pulp. It adopts the high quality of stainless steel 304 material, meets the requirements of food grade. It is full automatic and advanced in construction, steadily in performance, safe in operation, easy in maintenance, high in production efficiency. The filler is the ideal choice for drink factories of small and middle size.

Technical Parameter

| Technical parameter :soft drink can filling sealing machine |

|

| Model | GD12-1 | GD18-4 | GD24-4 | GD32-6 | GD40-8 |

| Capacity (cans/hour) | 2000 | 8000 | 10000 | 15000 | 20000 |

| Suitable bottle shapes | Pop can / Tin can / PET can |

Bottle diameter(mm)

| Dia50 ~ Dia99mm |

| Bottle height (mm) | 70-133mm |

| Filling type | Isobaric filling / Normal pressure filling |

| Application | soft drink can filling sealing machine |

| Total power (KW) | 2.4kw | 4.5kw | 5.2kw | 5.2kw | 7.2kw |

| Overall dimensions | 2.5*1.9m | 2.8*1.9m | 3.2*2.2m | 3.4*2.5m | 3.4*2.5m |

| Height | 2.3m | 2.5m | 2.5m | 2.5m | 2.5m |

| Weight(kg) | 2000kg | 3500kg | 4500kg | 5000kg | 7500kg |

|Customer Production

| More Products

Focus on intergrated solution for beverage and liquid food, such as Mineral drinking water, Fruit Juice, Carbonated beverage,Energy drinks,Alcohol Wine, Beer, Edible oil, Dairy and Dauily care products, etc.

|Complete Line Solution

1.Pure water treatment filter system

This RO system is very important in the whole water project, we prefer you supply water analysis report from your local inspection department. This RO system we can make to match up with your water filling machine from capacity from 500L/Hr to 50000L/hr.

This system included sand filter, carbon filter, sodium exchanger, precision filter, Reverse Osmosis, UV, Ozone generator, Ozonized Tower, Pure water tank. This system is made of SUS304 or SUS316 material, thickness is 2.5mm-3mm we promised.We use GNP or CNP water pump, USA DOW or HYDRANAUTICS membrane, etc

2.Beverage blending system

Wide range of uses - The system can handle a wide range of products such as carbonated drinks, juice drinks, etc. Easy power adjustment - easy adjustment of mixing ratio without having to replace parts. Structural Hygiene - All parts in contact with fluids are of high-quality stainless steel, all tanks are equipped with a CIP ball for easy cleaning.

Accurate mixing accuracy - product mixing accuracy G ≤ 2%.

3.Cans depalletizer

Aluminum can depalletizer, it is designed to handle empty cans from pallets and transfer, layer by layer, onto the production line.Aluminum can washing, it is revolution inclined type can.Automatic destacking machine is mainly suitable for the whole crib tin (cans) automatic destacking empty cans, it will be stacked on the pallet empty cans, bottom-up layers of ascension and layered pushed to the path of the conveyor chain, with empty cans of spray cans machine use, replace artificial row of cans and traditional empty cans of unloading tank machine, can save a lot of artificial, increase production capacity.

4.Automatic Food Soft Energy Drinks Fruit Juice Beer Carbonated Beverage Aluminum Can Filling Line and Seaming Machine

The machine is suitable for filling and sealing beverage or brewage industry ,it have such features as rapid filling and sealing speed ,consistent height from the liquid level in the can to the can mouth after filling ,stable machine operation ,good sealing quality ,beautiful and decent appearance ,convenient use and maintenance ,touch screen operation ,frequency conversion speed adjustment ,etc.it is the most ideal filling and sealing device for beverage plants and brew houses

5.Can Warming tunnel.

Conveyor brings bottles into the cooling tunnel, there will be cooling water generated from side holding tanks to spray by spray

nozzles on the top of tunnel onto passing bottles. With heat exchange principle, the bottles temperature will be low down to

normal room temperature to increase product shelf time. All body material is high quality SUS304; The transportation is by

engineering plastic chain.

|Turkey Project

Carbonated Drink/Water/Juice Production Line

1 / Preparing System (Aseptic water storage tank, Sugar melting tank & syrup filter, Flavour blending tank & syrup cooler, Flavour blending tank & syrup cooler, Co2 drink mixer & Co2 filter, Water chiller )

2 / Water Treatment Syatem (quartz sand filter, active carbon filter, softner, RO system and so on)

3 / Empty can unloading machine

4 / Slide - type empty tank spray washer

5 / Can juice/csd drink filling sealing 2 in 1 monoblock

6 / Spray sterilizing chiller (including local control cabinet and electrical control device)

7 / Shrink labeling machine

8 / Wrapping machine

|Company Info

ZHANGJIAGANG MAERCK PACKING MACHINER CO.,LTD.

Zhangjiagang Merckpack Machiney Co., Ltd. was founded in 2004, our company covers an area of 15000m2. We are a leading enterprise in research and production of liquid and beverage packing machines. Our main products includes: water treatment plant, beverage and daily chemical filling machine, labeling machine, film shrink wrapping and carton packing machine, beverage processing and production lines.

We are not only a machine manufacturer, we can also supply turnkey project according to customers’ request, including workshop design, machine layout design, water, gas, electric cable layout design, label and bottle design and so on. Our mission is to ensure customers’ plant properly working and help customers win their market.

Different capacity small bottle mineral water filling machine

8-8-3 Bottle Water Filling Line Capacity:1000-2000 bottles per hour.

14-12-5 Bottle Water Filling Line Capacity:2000-3000 bottles per hour.

16-12-6 Bottle Water Filling Line Capacity:4000-6000 bottles per hour.

18-18-6 Bottle Water Filling Line Capacity:6000-8000 bottles per hour.

24-24-8 Bottle Water Filling Line Capacity:10000-12000 bottles per hour.

32-32-10 Bottle Water Filling Line Capacity:12000-15000 bottles per hour.

40-40-12 Bottle Water Filling Line Capacity:20000-24000 bottles per hour

| FAQ

1.Q For a new starter, how can you help me start and run a water or beverage bottling plant?

A We can help you do the bottle design, label design and choose the suitable labeling and package type according to your local market. If you have confirm the factory size, we can also make the machine layout design accordingly. We can help you install the machines, train your staff how to operate, maintain the machines and even help you hire experienced Chinese engineer to work in your factory as a production manager.

2.Q What is the guarantee or warranty of your machines?

A We give 18 months warranty for the mechanical parts and 12 months warranty for the electric parts.

3.Q How can we check our machines if we order the machines from you?

A We will test all the machines before shipment, you can come to inspect the machines or we can take videos for you.

4.Q How can I know the quality of your machines before I order?

A We have many projects in different countries, with the customers’ permission, we can guide you to visit the factories and see the machines running.You are also very welcome to visit our company in China to see the machine running in our factory.

5.Q Can your company provide turnkey project from A to Z?

A Yes, we can provide the turnkey project for beverage production line, from PET preform and cap making machine, PET bottle blowing machine, water treatment plant, juice or carbonated drink mixing plant, filling and packing machines.

Zora Xu

Zhangjiagang Merckpack Machinery Co.,Ltd

Mobile phone:0086 13773222879